February 2026

LIFE INSIDE THE FACTORY

H. Forman & Son's smokehouse on Fish Island

Forget your sleepy 9-to-5. At H. Forman & Son’s smokehouse on Fish Island, the day kicks off when most of London is still dreaming, and it revolves around three non-negotiables: ridiculously fresh Scottish salmon, the legendary London Cure, and craftsmanship dating back 120 years.

The crack-of-dawn salmon drop

Before the sun even thinks about rising, carts of iced Scottish salmon start rolling in, each fish making the journey from Scottish waters to us in under 48 hours. Why the rush? Because fresh fish is firm fish, and firm fish is the only kind that can handle what comes next.

In the chilled prep rooms, the filleting crew moves with the kind of speed and precision that would make a sushi chef nod in respect. They’re cleaning, boning, and splitting every fish entirely by hand, eyeballing each one with a critical gaze. Standards aren’t just high here, they’re non-negotiable.

Salt, dry, repeat (but make it artisanal)

Once the fillets pass inspection, they hit the salting racks where they get a gentle sprinkle of rock salt, just enough to draw out 10% of each salmon’s weight in water. The salmon is then hung up to dry, where the warm air draws out another 10%, the traditional way to preserve salmon that also prepares it texturally for the smoking.

The smoke show (literally)

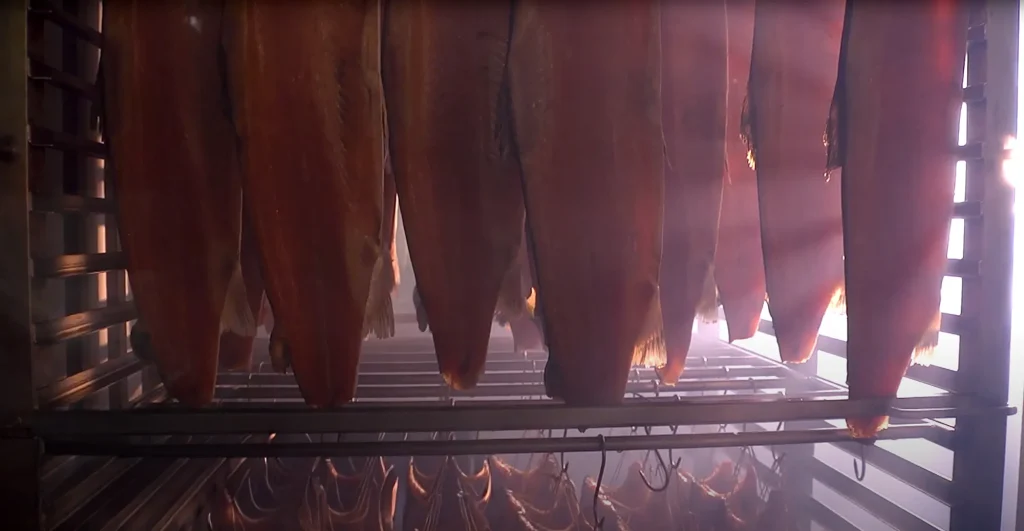

After a thorough rinse, the salmon sides get their moment in the spotlight, or rather, the kiln. But this isn’t your backyard BBQ situation. Instead of chunking logs into a fire, Forman’s uses a friction system that gently coaxes smoke from sustainable oak, keeping everything cool and controlled.

The goal? To kiss the fish with smoke, not smother it in a choking cloud. The salmon emerges with just enough smoky character to enhance its natural flavor, not bulldoze it.

Tweezer experts and carving maestros

Now comes the part that separates the pros from the pretenders: trimming, pin-boning, and slicing. Armed with tweezers and wicked-sharp carving knives, the team plucks out every microscopic pin bone (and trust me, there are loads) before hand-carving the salmon into those gorgeous, paper-thin slices you see in our packages.

This isn’t something you learn on YouTube. It takes years to master the angle, the pressure, the rhythm. Machines? They’d butcher the delicate flesh. This job demands human hands, human skill, and human patience.